|

Engineering calculations

before the transistor.

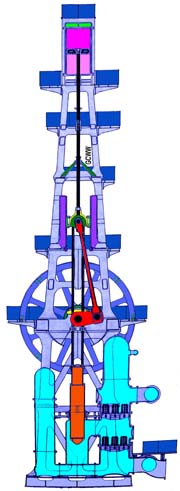

Side View

R.D. Wood

Triple Expansion

Crank & Flywheel

Water Pumping

Steam Engine

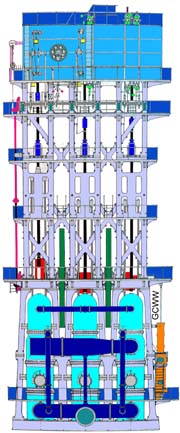

Front View

^Top^

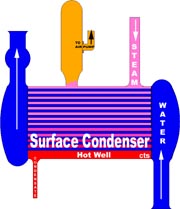

Surface Condenser

R.D. Wood Engines

^Top^

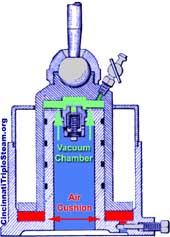

Dual Chamber Vacuum

Dashpot

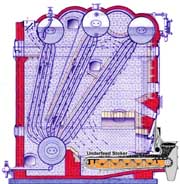

Stirling 4-drum

Water-Tube Boiler

with

American Underfeed Stoker

3-Steam Drums,

1-Mud Drum

Stirling 4-Drum

Water-Tube Boiler

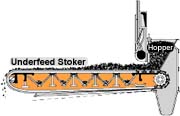

American Underfeed Stoker

^Top^

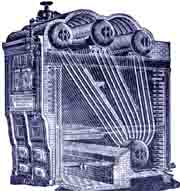

Exhaust Heater

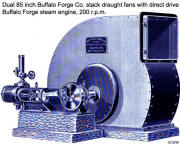

85 inch Buffalo Forge stack draught fan with direct drive Buffalo

Forge engine

Berryman Feed Water Heater

and grease separator

for support engines

Wheeler Surface Condenser fitted with a

Mullan Valveless Air Pump

for the support engines

^Top^

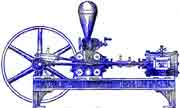

H.R. Worthington

Feed Water Pump

for support engines

Click to expand

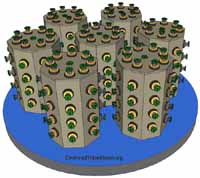

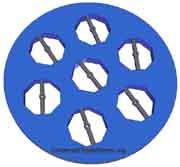

One of 7 Poppet Valve Cages

40 Valves/Cage

in each of two

assemblies

for each

of three pumps

^Top^

Pump Poppet Valve Assembly

7 cages @ 40 valves/cage

Pump Valve Assembly Base

Water Pump Poppet Valve

|

|

Building Design |

Cincinnati Architect, Gustave W.

Drach |

|

Engine Design |

John H. Lewis - R. D. Wood & Company

400 Chestnut St.- Philadelphia, PA |

|

Engine Manufacture |

Camden Iron Works, Camden, New Jersey |

| Engine Type |

Vertical triple

expansion crank & flywheel |

| Bids from |

Lane & Bodley Company of Cincinnati, Ohio originally won the

contract to supply the engines. After two yeas of

non-performance and an unfavorable decision by the Ohio

Supreme Court, their contract was canceled and the re-bid

was among the following: Camden Iron Works,

Camden, NJ

Holly Mfg., Lockport, NY

E. P. Allis Co. Milwaukee, WI

Kilby Mfg. Co. Cleveland, OH |

|

Cost |

Engines, Boilers & Overhead Crane, $1,331,000 |

| Service |

October 29, 1906 to

May, 1963 |

| High pressure cylinder |

29

inches diameter. 150 p.s.i.g. |

|

First receiver |

27 p.s.i.g. |

| Intermediate pressure cylinder |

54

inches diameter |

|

Second receiver |

-2 p.s.i.g. |

| Low

pressure cylinder |

82

inches diameter, 22 inch exhaust port |

| Re-heaters |

2 |

|

Surface area of re-heater |

1st =122 ft2

and 2nd

=276 ft2 |

| Stroke |

96 inch |

| Steam pressure |

150 p.s.i.g. |

| Efficiency |

21.6% coal to

water. See

Coal to Water Efficiency |

| Steam valve

gearing |

Corliss with dual chamber vacuum dashpot for the HP

cylinder and the inlet to the IP cylinder.

Balanced Poppet on the exhaust for the IP cylinder

and for both the inlet and exhaust on the LP cylinder (inlet

spring loaded, exhaust weight loaded) |

| R.P.M. |

15.5 (range 11 to

15.5) |

| Piston speed |

248

feet/minute or 2.82 m.p.h. |

| Horse power |

1,000 |

| Flywheel |

2 x 24

feet diameter, 40 ton, assembled in sections and secured

with dog bone locking keys. |

| Starting/Stopping |

The traditional Barring engine (also called a Jacking engine

or Kicking engine) was not used to start this engine.

Instead, the engine was rolled using the procedure listed

below. (nominal process steam was 150 p.s.i.g.)

Start engine procedure:*

- Preheat engine setting jacket steam and re-heater

steam to 65 p.s.i.g.

- Begin oil drips 10-15 minutes prior to starting.

- Open engine drains to bypass steam traps.

- Adjust air pressure in both the suction and the

discharge force chambers.

- Load the water pumps using the bypass source

until about 65 p.s.i.g.

- Open the main water inlet valve prior to opening main

discharge valve. Later on cone valves replaced the gate

valves and required verification of 200 p.s.i.g. water

pressure

for cone valve operation.

- Set governor to lowest speed

Roll engine by:

- Charging the first receiver to 30 p.s.i.g. steam.

- Slowly apply process steam to the HP cylinder until

about -7 p.s.i.g. is achieved in the condenser and throttle

back until the condenser achieves -13

p.s.i.g., and the governor has kicked in.

- If the HP piston is at dead center for crank-end or

head-end, the overhead crane is used to nudge the

flywheel off dead center.

- Close bypass to first receiver and adjust to about

22-24 p.s.i.g.

- Close drains and check for about -5 p.s.i.g. in the

second receiver.

- Slowly bring engine to operating speed.

- Check dashpots and valves for proper operation

- In case of trouble or emergency, knock out the vacuum breaker and

the engine will immediately stop.

Stopping the engine in normal operating conditions required skill and practice to

prevent the HP cylinder from ending at TDC.

* Starting procedure from

Stationary Engineer Jim Hoctor Sr. operating notes and input

from Paul Kraus. |

|

Bearing Gland Packing |

Initially oakum impregnated with paraffin and later on

asbestos impregnated with graphite |

|

Length of eccentric

shaft |

30 feet |

| Length of main

shaft |

10 foot 2

inches |

| Diameter of main

shaft |

19

inches |

| Length of main

shaft journals |

28

inches |

| Diameter of main

shaft journals |

19

inches |

| Length of crank

pin journal |

10

inches |

| Diameter of crank

pin journal |

High pressure and low pressure journal, 10 inches.

Intermediate pressure journal, 14 inches |

| Length of cross

head pin journal |

10

inches |

| Diameter cross

head pin journal |

10

inches |

| Weight |

1,400 ton |

| Height |

104

feet |

|

Base, cast iron |

23 foot 7 inch deep X 36 foot 4 inch wide x

28 inch tall |

|

Working decks |

11

decks accessed by stairs and elevator. The cast iron valve

decks were replaced with cast steel decks in 1915 |

|

Ancillary

Equipment

Attached |

A surface condenser,

wet air pump, boiler feed pump, air compressor, bilge pump,

and exhaust

heater |

| Condenser |

The attached surface condenser is

located in line with the 48 inch discharge header with the entire

water discharge passing

through it.

In addition, two Wheeler surface condensers each equipped

with a Mullan air pump were in the boiler room to handle the

exhaust steam from the ancillary engines |

| Condenser size |

62 inch diameter x 12 feet, 4 3/4

inches

long |

|

Condenser pressure |

-13.8 p.s.i.g.

nominal |

| Condensing surface |

2,130 ft2 |

|

Air compressor, attached |

3 3/8 inch plunger X 96 inch stroke |

|

Bilge pump, attached |

3 inch plunger X 96 inch stroke |

|

Boiler feed water pump, attached |

2 3/4 inch plunger X 96 inch stroke |

|

Wet air pump, attached |

28 inch diameter X 30 inch stroke |

| |

|

| Heating surface of

exhaust heater |

150 sq. ft. |

|

Ancillary Equipment Detached |

|

|

Boiler feed water pumps |

2- Henry R.

Worthington 10" x 6" x10" |

|

Boiler feed water pump for auxiliary equipment |

1- Berryman |

| Detached air

compressor |

by Westinghouse |

|

Pumps |

|

| Pumps/engine |

3 |

| Pump type |

Plunger,

a nickel iron plungers replaced all the cast iron plungers in

1932. |

|

Pump plunger |

Diameter =

3 1/8 feet or 37.5 inches, Length = 14 feet

24 Tons |

| Diameter of pump

barrel |

54 inch outside

packed |

| Diameter of pump

valve force chamber |

74 inches |

| Pumping

capacity/engine GPD *** |

Rated at 30,000,000 rated; Tested at 30, 878,124 |

| Gallons/Revolution |

Rated at 1,361.7, tested at 1,377 |

| Tons

of water moved / Revolution |

11.46 tons/engine, 45.84 tons/station/revolution |

| Stroke |

96

inches |

| Inlet nozzle |

48 inch to engine header, 40 inch to pump |

| Outlet nozzle |

40 inch to header,

48 inch to dual

60 inch outlets |

| Discharge pressure |

60

p.s.i.g. nominal |

| Effective area of

pump valves/pump |

1,665 sq in which is 51% above plunger area |

| Suction

poppet valves/pump |

280 at 3.5 inch OD, 7 cages, 40 valves/cage |

| Discharge

poppet valves/pump |

280 at 3.5 inch OD, 7 cages, 40 valves/cage |

|

Boilers |

|

| Boilers |

9-Stirling water tube boilers, eight at 424 HP and one at

529 HP, plant h.p. = 4,500 in 1921.

New boilers in 1920 and 1921

In 1906 the Stirling Company, with works in Barberton, Ohio, merged with Babcock and Wilcox

of New York. |

| Coal feed |

American underfeed

stokers, later on, Forced draught Riley

Stokers |

| Boiler tubes |

176 tubes, 3

inch diameter |

| Steam drums |

3 at diameter

of 36

inch , length 10 feet 9 inches |

| Mud drum |

42 inch X 9 feet 3 inches. |

| Steam pressure |

150

p.s.i.g. |

| Seam piping |

Fourteen inch pipe

delivers steam to the engine room arranged to use either

saturated or super-heated steam and branches into two lines

with two engines taking steam from each branch.

Exhaust steam from the LP cylinder flows through the

exhaust heater into the condenser. The air pump removed air,

oxygen, CO2 and uncondensed steam from the condensate chamber while

maintaining a near perfect vacuum (-13.8 psig) in the chamber. |

| Steam moisture |

2.2% at engine, 2%

at boiler |

| Heat boosters |

Green Economizer: Steel tube boiler feed-water heater

Foster super-heater: is a drawn

steel tube with cast iron radial fins heat shrunk onto the

tubing and allows better heat transfer from boiler gases to

steam than tubing without fins. The foster

Super-heater added 100°F to the steam

temperature and contributed another 200 HP

Auxiliary Hearer: exhaust steam from the ancillary engines

flowed through a Berryman type boiler feed water heater

and grease separator prior to entering the Green Economizer. |

| Gases leaving

boiler |

437°F |

|

Gases leaving super heater |

373°F |

|

Stack temperature |

196°F |

| Water evaporated

per 1 lb. dry coal |

10.687 lb., boiler

contribution 95%, economizer contribution 5% |

|

Condensate from the R. D. Wood Engines |

Boiler feed water

originated in the hot well for the surface condenser and was

collected in dual condensate storage tanks where the boiler

feed pump attached to the main engine takes suction.

From there water was forced by the attached feed pump

through the exhaust heater, through the deaerating plant,

through the auxiliary heater and through the Green

economizer into the boiler. Water from the softening and

deaerating plant was 92°F, increased to 142°F from

the exhaust heater and left the

economizer at 200°F.

Deaerating plant installed in 1922 |

|

Feed water from auxiliary engines |

Two 10 inch x 6 inch x 10 inch H. R. Worthington boiler feed

pumps. |

| Work duty coal |

Rated at 115,000,000 ft lb. of work for every 100

lb. of coal (Tested at 152,875,648 ft lb.)

See

Coal to Water Efficiency |

| Work duty steam |

172,925,997 ft lb. per

1,000 lb. of dry steam, weir measurement |

| Boiler House |

60 foot

X 180 foot,

Oolitic* dimensioned Bedford limestone, exterior rock faced, and inside sawed

smooth and rubbed. Boiler room floor of concrete, toilet

room red American tile, office and store room was matched yellow

pine flooring. Steel roof and lantern frame covered with

vitrified** "S" tile. Individual lockers for all employee,

toilet rooms with shower baths and other conveniences.

*Oolitic dimensioned limestone = grain size .25-2mm

**Vitrified Tile is a tile is created by the Vitrification

manufacturing process which has very low porosity and water

absorption, making it stain-resistant and strong. |

| Smokestack |

8 foot ID, 175 foot high of brick on circular stone base resting on a

concrete foundation with a diameter of 35 foot and 8 foot deep. The

stack is faced with light buff-colored radial Kittanning

pressed brick and topped with a cast-iron cap. Forced

draught

was provided by two 8 inch by 10 inch Buffalo Forge

Co. engines each direct driving an 85 inch Buffalo Forge Co.

fan , nominal R.P.M., 200. |

| Coal |

|

| Coal storage |

An elevated steel building supported by

steel columns, 69 foot X 225 foot kept the coal dry during

periods of high water and provided sufficient coal storage

for periods of low river level. 7,980 tons

were stored in 114 elevated pocket

hoppers each holding 70 tons, and equipped with a coal spout

valve leaving 6 1/2 feet of head room above the narrow

gauge tracks running lengthwise underneath the pocket hoppers. |

| Coal

usage |

26 tons (average daily) |

| Coal

supply |

Coal was originally received by barge and

occasionally by truck in the later days. A railroad siding

had been extended to the coal bunkers to provide for rail

delivery, but never use for that purpose. |

| Coal delivery |

Coal was elevated from river barges via a

dual narrow gauge rail system installed from low river water

level to the top of the three story coal hoisting house

using a steam hoist cable pull for dual two ton

capacity steel dump cars (one traveled up while the other

returned to river's edge) and deposited onto a cross belt conveyor,

and distributed by means of shuttle

belt conveyors to the 114 pocket hoppers. |

| Boiler coal

delivery (Coal Passers) |

Coal was

switched to the boiler house from the coal storage building

using a narrow gauge

rail system with boiler charging cars powered by an electric

locomotive engine about the size

of a golf cart, called the "Dinky". Boiler ash cars were switched using the same

locomotive. Coal was dumped on the floor in front of each

boiler and shoveled into the stoker hopper using coal shovelers.

1924, an overhead rail suspended hopper

system called the "Lorry" delivered coal to each stoker

hopper and was supplied by a coal hoist in a new three story

poured concrete lifting house at the front of the boiler

house. |

| Coal size |

Pittsburg Nut &

Slack which is 1 1/2 inch and 3/4 inch respectively provided 13,000

BTU

per pound of coal. |

|

Coal tests |

Moisture 2%, Ash from coal 8%, Slate in coal 1% |

| Pump Pit |

Built by F. H. Kirchner & Co., of

Cincinnati, the circular tapered, below grade wall, is 98 feet

inside diameter and 85 foot high, using circular sawed

Oolitic dimensioned

Bedford

Limestone* fifteen feet thick at the bottom and four

feet thick at the top with the inside face being plumb and

fine-pointed. The above grade masonry uses

a

Romanesque Revival architectural style with rock faced

Oolitic dimensioned Bedford limestone, and the inside lined with Tiffney white

enameled brick. Vitrified* "S" tile covers the conical roof |

| Steel Casing |

A masonry

embedded 1/4 inch

riveted and caulked steel cylinder extending from the pit

floor to 70 feet high assures a water tight pump pit. |

| Pit

floor |

85 feet below elevation, -5.5 feet below river bed |

| Foundation and

caisson |

128 feet

diameter by 12 feet thick solid 12" x 12"

air-dried white oak timber

crib foundation rest upon the 7 feet high tapered-edge

caisson cribbing using crisscrossed wood shoes with 21

excavation chambers. |

| Inlet stand pipe |

10 foot

diameter riveted steel setting on bedrock |

| Caisson ballast |

72 foot high

with an OD of 23

feet and an ID of

13 feet, cast iron, 4,200 ton, Individual sections weighing 6 ton each. |

| Station

Electrical Supply |

Three units,

each consisting of a DeLaval steam turbine driving two 75

KW, 4 pole Crocker Wheeler, 230 volt direct current

generators provided electricity to both river station

and the filtration/treatment plant. |

| Station

Elevator

and Stairs |

Warner Elevator Manufacturing Company

from Cincinnati, Ohio provided a 2,500 lb. capacity, 230 Vdc motor driven elevator

that traveled between the

engine operating floor level and the pump pit floor level. Two spiral stair cases extended from the pit floor to

the eccentric deck. A railed staircase extends from the

engine floor to the wheel deck. The railing for all stairs and elevated

walkways was bright work polished brass. |

| Overhead

Hoisting Crane |

From the Morgan Engineering Company,

Alliance Ohio, provided a 3 motor circular traveling radial

crane with a span of 49 feet 6 inches and a 30 ton lift of

110 feet. The electric motors use Morgan controllers with

adjustable speed and direction controls. All motors are 230 Vdc and included a

30 HP hoisting motor, a 25 HP a bridge

motor and a 5 HP trolley motor. The crane

was ordered on April 26, 1901 by the Camden Iron works

and shipped to the California, Ohio facility on November

18, 1903.

Design of the engine and its

pumps allowed every principal part to be

reached and removed by the overhead hoisting crane without

disturbing any other part of the machinery. |

| Operations |

Three engines

could be operated at rated capacity without increasing the

regular daily staffing of 36 employees. The Station

Chief was in charge of the entire operation while the

licensed stationary engineer was in charge of the engine

room and the licensed fireman was in charge of the boiler

house . Each eight

hour shift maintained a minimum staffing of one licensed stationary engineer, four oilers,

one licensed fireman, two coal-passers, and an assistant Chief

Engineer. Daily staffing include a clerk, one machinist and

helper, one boiler cleaner, one locomotive operator, a

janitor, and three or four grounds keepers.. |

|

Number of steam engines at River Station (21) |

4 - water pumping engines, R.D. Wood

4 - economizer engines

2 - stack draught engines, Buffalo Forge Co.

2 - boiler feed water engines for pumping condensate from

ancillary engines and ancillary equipment , Henry R.

Worthington

9 - stoker engines |

|

* * * GPD, Gallons Per day |

|